Bharat TRIZutsav® India’s annual TRIZ and Technical Innovation conference to promote and showcase Invent in India®

ATTI with PROINN® is contributing to Atma Nirbhar Bharat on technical innovation

October 30 -31, ONLINE 5 PM – 9 PM IST

The 5th Edition is being brought to inspire Indian professionals to Invent in India® and how we can build Atma Nirbhar Bharat in Innovation and Technology Development

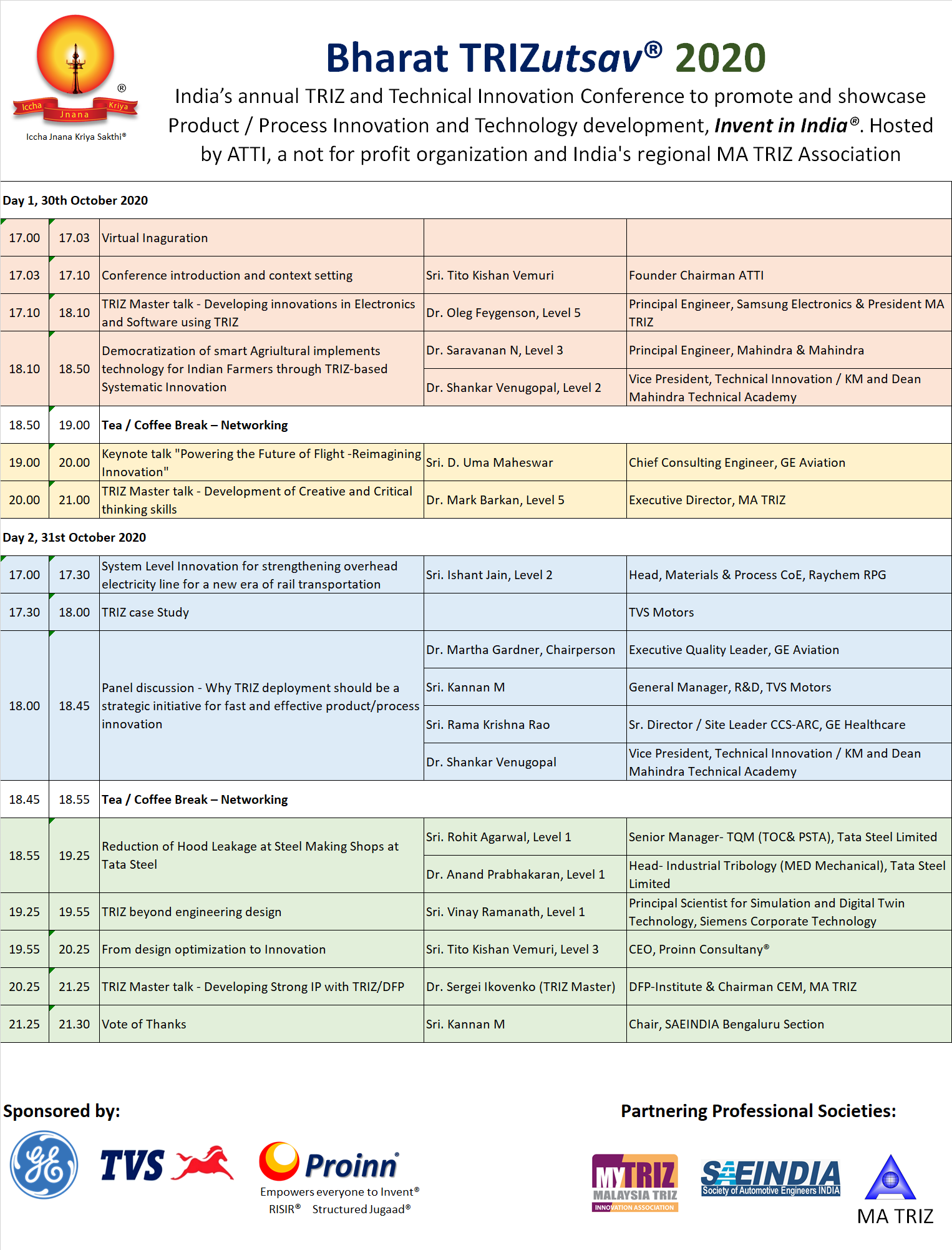

Conference Agenda